CNC Router

Capabilities

What's Possible

- 120″ x 48″ x 12″ cutting area. The gantry is 8″ from the table top.

- Open ended for stock and panels larger then 24″ long

- 4HP Hitecho spindle with ER20 collet – Can accept up to 1/2″ shank tooling

- 1/32 up to 1/2″ solid carbide end two flute endmills

- Compression bits used on sheet goods to avoid tear out

- “O” flute or single flute endmills for cutting plastic

- 2 1/2″ face mill for flattening flabs and panel glue ups.

- Rapid travel speeds up to 1000 IPM and cutting feed rates up to 500 IPM

- Linear rail guides and bushings driven by rack and pinion

- Precision ball screw extended 12″ Z axis

- Custom vacuum table with built in T tracks

- 2D part cut outs and engraving

- 3D relief carvings and part machining

- Plywood and other sheet goods

- Hardwoods

- Plastics

- Aluminum

- Product nesting

- V carves

- Name engraving

- Wood graphic inlays

- Slab and panel flattening

- Seat cutouts

3D Carving

Carving on a pine bench that was donated to a Pheasants Forever banquet.

Graphic Inlays

Maple inlays in a walnut cutting board.

Cutouts

Baltic birch cutouts for crafting,

Custom Signs

Custom sign work all cut out on the CNC.

Walnut Carving

Dog and duck carving done in walnut.

-

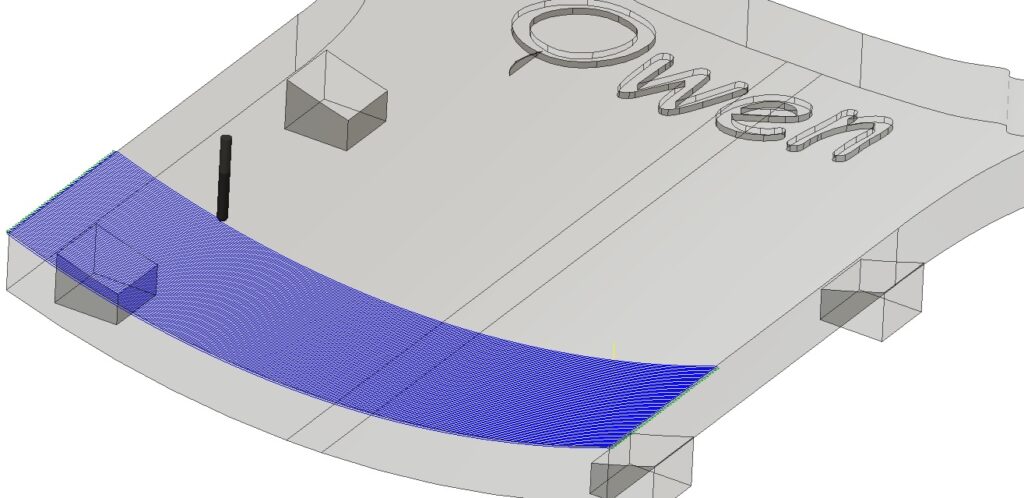

In House Design & Programming

It's important to have the skills and knowledge to design and program our self. We utilize a subscription to Autodesk Fusion 360 for both CAD and CAM uses.

-

File Types

Autodesk accepts a wide range of file types. Some of our more commonly used files include .SVG, .DXF, .STP, .STL, and .IGES files.

-

Program Simulation

To ensure accurate finished products and a failure free program, we run simulators on all of our programs. It allows us to catch potential issues and correct them before they see production.

Workshop Videos

Playlist

4 Videos